Let the marketplace become your sales force, says Mr. Loadlink upon his return from Asian peregrination.

There have been two stages to the SP revolution. First, industry started to refer to SP Radiolink pluses and SP Wireless Loadshackles etc.; now, many engineers are driving the brand towards synonymity with all requirements for force measurement, load monitoring and suspended weighing load cell technology, regardless of the specific product required.

There have been two stages to the SP revolution. First, industry started to refer to SP Radiolink pluses and SP Wireless Loadshackles etc.; now, many engineers are driving the brand towards synonymity with all requirements for force measurement, load monitoring and suspended weighing load cell technology, regardless of the specific product required.

“You’ll need an SP for that,” she said, looking at the job spec requirements to perform load tests on a 400t capacity deck crane aboard a vessel. This particular engineer, like many of her peers the world over, simply identified a need for a low headroom load cell and knew Straightpoint could provide the solution. In a completely unrelated email I received recently, the same assumption was made: “Can you help me source an SP package to measure this load before we order the crane?” it read.

Family values

It’s a heady status that the whole Straightpoint family has been working towards for many years, in earnest since we launched the new ‘SP’ logo, say, five years ago. Yet the marketplace is driving it; they’ve become our sales force.

We’re not getting ahead of ourselves and it certainly doesn’t represent the completion of any journeys—only another milestone—but it’s something we’re extremely proud of. Where Tannoy might be used to describe a public address system, or one might buy a Coke neglectful of the brand of fizzy drink available before Hoovering the carpet, SP will one day be used just as ubiquitously in the rigging industry.

Consider that there will always be more weighing requirements than there are Straightpoint personnel or distributors, and think how powerful ‘SP’ could become. As such, I thought it prudent to share in brief the four main reasons, in no particular order, why this evolution has taken place, in the hope readers might be able to apply similar strategy to their own businesses. Remember, our starting point can be likened to many other companies; we started off small in a market with a number of much larger competitors.

- Quality

Engineers don’t give compliments easily. They understand materials, structures and systems as they relate to their fields of expertise. They identify problems and set about finding solutions. Thus, only by providing a world-class product, backed by a dedicated distributor network, has SP become associated with the positive impact it can have on an industry, jobsite or application. Ironically, it takes an incredibly reliable and efficient product to achieve secondary status to a brand.

- Diversity

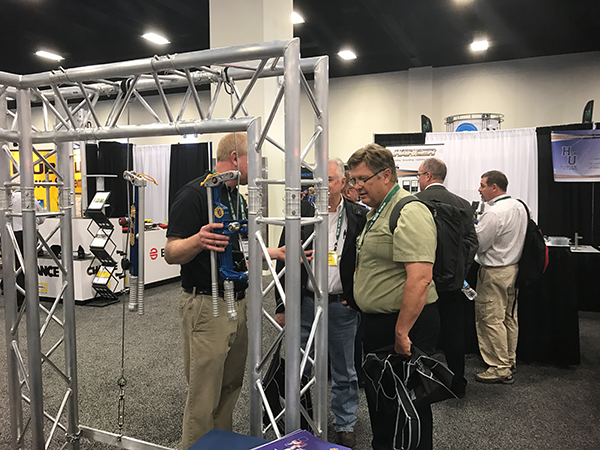

It’s taken constant diversification and enhancement of the SP range to differentiate us from alternative solution providers. As our new Clamp On Line Tensionmeter (COLT), specifically targeted at the plumb and tension market, proves, we can tailor solutions for end user marketplaces. Of course, the National Association of Tower Erectors (NATE) community—we launched the product at their event—isn’t shouting about SP from the rooftops yet, but it is getting its first taste of the comprehensive range of equipment that provides solutions for such varied applications.

The engineer referenced at the outset wouldn’t have said, “You’ll need an SP for that,” unless she trusted the brand to cater for all application nuances. She’d have said, “We need to find a load cell supplier that can work with these headroom restrictions.”

- Marketing

Visibility and consistency of marketing message has given the marketplace faith that we are sincere about our endeavours to make the lifting industry a safer place. Backed by a simple but effective and recognisable logo, we have associated the SP concept with a commitment to make a positive difference to the way industries across the world use cranes and other equipment. Through non-commercial blogs, press releases, advertisements, social media, trade shows and more, we’ve been authentic and ever-present.

- Internationalisation

SP means the same in any language. It’s easy and fast to say, meaning non-English speaking distributors and their customers have been particularly keen to adopt the abbreviation. The effectiveness of our product in meeting local requirements has also endeared us to different geographies. Regulations are different in the UK, Australia, China and the Middle East, but we have ensured our range can be used everywhere. SP would never have caught on if it only provided a solution in certain industries or regions.

Rising in the East

The evolution of Straightpoint to the point where SP has become a solution in its own right was particularly apparent during a recent trip that saw me visit the Middle East, Korea, Malaysia and Indonesia in quick succession.

First, I was honoured to be a guest of Gaylin International and Rigmarine (part of the Gaylin Group) in Dubai, where I was among a select group of manufacturers—Modulift, William Hackett and Samson Rope were also there—invited to network and give a presentation to representatives from 10 locations around the world. I’m grateful to Mike Duncan, managing director of Gaylin, for the opportunity, which I also used to spend some time with the company’s CEO, Desmond Teo and his team.

From the Middle East, I flew out to visit Borneo-based lifting and rigging equipment supplier Leyden Engineering Services, which is based in Labuan, a territory of Malaysia off the coast in East Malaysia. There, I conducted training and participated in meetings with the company’s founder, Anthony Ho; his son, Chiang Seng Ho; and other representatives, all of whom spoke highly of the “SP” range.

- Talking SP at Leyden.

- A stunning Borneo sunset.

- No blog that references Leyden Engineering Services is complete without mentioning the fabulous local cuisine.

- Selfie time with Leyden’s Anthony Ho.

As an aside, it was interesting to visit a local museum to learn of the region’s history and, in particular, the importance of coal during British colonisation. I’ve blogged before about the area’s stunning seafood!

In between activity with Leyden I visited a local museum. This plaque reads, ‘Here, on the 10th September, 1945, the commander of the 9th Division, Australian Imperial Forces, received the surrender of the 37th Japanese Army in North Borneo’.

Next stop was Batam, Indonesia, home to PT Rigspek Perkasa, a distributor across a key region of Southeast Asia and Oceania, where Erald Bangapadang was a fantastic host. It was interesting to note synergies between his company and Leyden, who both see a lot of potential for the SP COLT and wireless compression load cells. Driving demand for the latter is local customers increasingly seeing the importance of getting information about loads before sourcing lifting equipment or instructing a lift. As Asia and the US catch up with Europe in terms of pre-lift preparation, the future for these load cells is exciting.

- PT Rigspek Perkasa is a distributor across a key region of Southeast Asia and Oceania.

- An overhead crane at Rigspek.

- Out in the Batam sunshine with Erald Bangapadang and the Rigspek team.

- Crane spotting in the Rigspek yard.

Tailor-made

In other news, we completed a record first quarter and have recruited industry stalwart Mike Neal as project sales engineer. He will utilise over three decades of relevant experience to primarily focus on promoting the company’s range of non-standard products. As I said in a press release, we want to increase our conversion rate on non-standard products to somewhere close to that of our standard range. He was actually my sales manager many years ago and we have kept in touch since; it’s great to have him on board.

There was one more announcement to make but I might save it until next month as Dean Nelson, managing director of Melbourne, Australia’s Hoisting Equipment Specialist (Vic) Pty Ltd is about to arrive and he’s had a long journey. Watch this space!

Thank you for reading and use the hashtag #loadcell on social media.

Mr. Loadlink