Constant evolution of a product range is a hallmark of a company thriving in the fast lane—but none of them would be there without their customers, says Mr. Loadlink.

Henry Ford was a business magnate

Henry Ford’s quote about horses needs closer examination. You know the one, where he says he wouldn’t ask his customers what they want because they would reply, “faster horses”.

I’m not sure it even exists in a directly attributable form but many versions of the tale go that the founder of the Ford Motor Company sneered at the idea that his audience—prospective drivers of automobiles—held the key to development of his business. The suggestion is that if his marketplace were responsible for its own advancement it would have considered a thoroughbred programme long before it looked beyond riding on horseback to powered transportation.

Whether Ford uttered these words or not, it would be a mistake to hold them up in isolation as a pearl of wisdom. And I’m sure even he wouldn’t do so. To suggest a market, consumer or otherwise, is blind to its potential is naive. Of course, it sometimes takes the innovation of manufacturers or suppliers at the sharp end of their sectors to drive certain change (surely Apple was innovating at a faster pace than its customers dared even dream, for example) but audiences mustn’t be viewed as a brake or anchor, holding back progression.

Take the “faster horses” quote literally and it implies the secret to a company’s success is darkened windows, high walls, and the type of switchboard that never actually delivers a caller to another human being. It champions isolation and arrogance—not characteristics we hope our own businesses are known for. Further, the theory renders market research useless and customer feedback a waste of time.

I certainly wouldn’t want to run my company without the valuable input of those distributing and consuming our equipment.

The famous “faster horses” quote attributed to Henry Ford is a conversation starter.

In fact, it is in unison with the marketplace that Straightpoint (SP) continues to pioneer the development of force measurement technologies, principally in below-the-hook applications but also through diversity in other sectors. Sometimes an innovation is conceptualised independent of industry in our workshop, while oftentimes a shortcoming of an existing product or opportunity for enhancement is put to us by an individual or demographic in the market. In a sense, the driver and passenger roles are switched, as should be the case on any long journey. Tiredness kills, as highway safety messages tell us.

Preaching to the choir

We don’t preach that we’re, “Making the lifting industry a safer place,” to an audience at odds with the concept; we’re united in our quest. Safety isn’t our idea. I don’t know how much the brilliant Ford Motor Company’s customers have had to do with development and evolution of the automobile but I reckon it’s been quite a lot. It’s unlikely that every knob, button, feature, dial, and gizmo has been produced without market input, as Mr. Ford would agree.

One could argue that modern-day Ford remains somewhat autonomous in approach. A tagline on the company’s website reads, “Our People Move Us”, although that could be taken two ways. It adds, “We don’t just build vehicles—we shape the future. Our team creates inspired products and services that help make people’s lives better.” There’s certainly some consistency there with firm’s history but just as I believe it always has, Ford cares passionately about its customers and listens to them intently. An article on its site talks about measuring customer satisfaction through quality surveys to that end.

I have no intent, and certainly no agenda, in shining a spotlight on Ford, nor does SP have any particular synergy with the car manufacturer. But it serves as a signpost to the fact that the best companies innovate, almost insatiably, to improve the lives of those that use their products. And they nearly always get help doing so.

My current trip to Asia—I’m on the last leg in Thailand, having already visited Vietnam, South Korea, Japan, Malaysia, and Singapore—is proof of that.

Good companies focus on product innovation, helped by their audiences.

Rising in the east

Here in the east, our new two-year warranty programme, as standard; DNV GL Type Approval Certificate; and Bluetooth app, for example, have been welcomed by a marketplace that can take huge credit for driving our business forward. SP’s ingenuity and craftsmanship alone wouldn’t have been enough; we may have been stuck with the fastest horse. To truly lead a curve and / or change the way an industry works, it’s a two-way street.

Sho Hiramatsu, of RUD Lifting Japan Co. Ltd., and the team are just one example of an engaged, regional partner helping us transfer feedback from the coalface into product innovation.

An engaged audience always greets us at RUD Lifting Japan

The DNV GL Type Approval Certificate, which says our Loadlink plus, Radiolink plus, and Wirelink plus products comply with DNVGL-ST-0378, the standard for offshore and platform lifting appliances, was a collective achievement with offshore professionals that use SP kit. In turn, we offer such purchasing decision makers even greater confidence in the load cells’ performance on all vessels classed by DNV. We already had 100% faith in the products’ ability to perform even in the world’s most demanding industries but what DNV approval does is verify to end users that our entire operation, from the smelting of the aluminium we use to application of product on site, meets certain requirements.

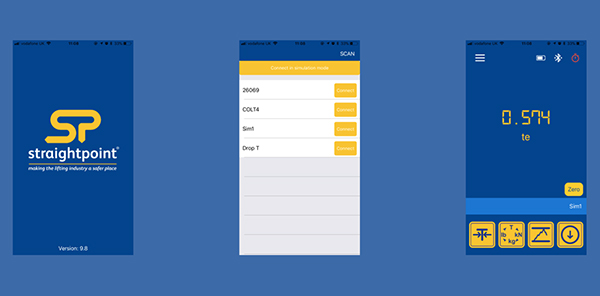

While our new Bluetooth app for smart devices, named after our Handheld plus display unit, is set to revolutionise the way data is captured and supplied in below-the-hook and other force measurement applications, we can’t take all the credit. Distributors and partners have lauded its ability to send reports from the same device that captures the data, and noted the inherent convenience of having the app on a smart device that is on their person, largely because they inspired such features. Sho’s market is particularly receptive to the technology.

Our new Bluetooth app for smart devices is named after SP’s Handheld plus display unit

Birds of a feather

My latest Asian tour has reinforced two facts: one, the fastest growing, most dynamic companies in the lifting marketplace are also the most innovative; and, two, distributorships note hallmarks of leading companies and find products of similar manufacturers to sell alongside them. It’s no coincidence that in Vietnam, South Korea, Japan, Malaysia, Singapore, Thailand, and many other places, I see SP equipment in workshops alongside the wares of fellow pioneers, such as Modulift, William Hackett, Crosby, and Elebia, to name just a few.

Regardless of the culture or customs of a geography, a reliable way to measure the success of a company visit or strength of a relationship is by the type of questions one is asked. When I’ve finished a product demonstration or introduced a new concept to a dealer, if an awkward silence precedes a boilerplate question like, “Is the Radiolink plus still your favourite product?” I immediately sense that the level of buy-in is much less than when a host of hands shoot up and I’m quizzed about the specifics of DNVGL-ST-0378 or the detail that can be included in the reports sent by the new Bluetooth app.

That goes back to the crux of this blog; customers drive a business forward. The string of record quarters we’ve had wouldn’t have been possible without feedback from the market—and travelling to get it first hand helps too.

Networking in Asia often involves sampling the region’s fabulous cuisine. I couldn’t sit like this to eat every day though!

On the tools

I’ll conclude with news that my son, Isaac, has joined Marcus MacDonald as an apprentice in our machine shop. As I blogged about last month, last time Marcus worked with an Ayling as an apprentice it was 1986 and we were on the same course. I wish Isaac (and Marcus!) the very best of luck.

Isaac Ayling (centre) with Marcus MacDonald (right), machine shop supervisor, and Gary White, production supervisor.

Now, back to my view of Chiang Rai.

Mr. Loadlink