In his final blog of 2015, Mr Loadlink reflects on the last event of a busy year, welcomes a new distributor, looks forward to unveiling a new member of staff and more.

It’s fitting that I’m sat beneath the largest drapery I have ever seen as I pen my last blog of 2015 and bring the curtain down on another year. Someone told me that here in the lobby of the Shangri-La Hotel in Dubai, where the LEEA Lifting & Rigging Conference Middle East took place earlier this week, two curtains on either side of the room each weigh over half a tonne in silk. I’d like to use a load cell to get an exact weight!

It’s been a big year for us too, during which I’ve clocked up more airmiles, visited more companies, attended more shows, signed off more press releases, sent more Tweets…you get the idea… than ever before. One final journey of 2015 remains from Dubai to Thailand, where I will spend Christmas and the New Year in the beautiful Chiang Rai region.

I will leave for the airport from the Shangri-La on Sheikh Zayed Road later today where, once again, the value of events that combine conference-style content with a small exhibition are fresh in the mind. I’ve said before that I find the visitors to such events hungry for information and prepared for serious conversations. I’ll set the scene again so you can look for similar concepts to add to your own event diaries in 2016.

LEEA, the trade association that underscores itself with the tagline Lifting Standards Worldwide, mirrored the format of the conference it staged in Singapore earlier in the year where we also had a positive experience. Here in Dubai, LEEA hired two ballrooms on the ninth floor of the hotel. A left at the registration table took one into a room named Al Bader, while a right turn took one in the direction of the equally grand Al Nojoom.

The event was, importantly, branded as a conference, which I think is key to attracting a certain audience. In Al Nojoom, two days of high level presentations took place from, say, 9am to 5pm, punctuated by breaks where attendees were ushered back into Al Bader. There, LEEA served a light breakfast on both mornings, lunches and short coffee breaks. During these sessions they were encouraged to peruse exhibits around the edges of the room and network.

Straightpoint had a stand opposite the door at the back in between our friends at Rigmarine and Modulift. It was a great feeling at breaks when traffic headed straight towards us. Each exhibitor had a tabletop for products and literature in addition to a small space to put up a couple of banners. As conference attendees filtered back from Al Nojoom, they were keen to interact and apply the products on show to some of the lessons they had learned across the corridor.

Community spirit

Quality took priority over quantity throughout the event. There was a community of, say, 100 engaged, switched-on people who absorbed world-class, educational content, cultivated contacts and met new professionals to add to their networks. Neither Al Nojoom or Al Bader were crammed to the rafters. Nor was there a queue around the corner when the doors opened. Instead, there was comfortable networking, interaction and constant sharing of information for continued improvement of best practice.

This is in stark contrast to many events where quantity almost takes precedence. Read the promotional materials for most trade events and they’ll make reference to miles of aisles, thousands of visitors, multiple days and even the need to book hotels early because of resultant chaos as the trade show rolls into town.

I often wonder who gains the most from this. Exhibitors can’t possibly engage with that level of footfall, visitors are hoarded into bottlenecks so organisers can take photos to make aisles look even more popular and similarly congested entrances, exits, hotels and restaurants become the norm. Imagine the freebees and brochures that are consumed by these hordes as they roam around booting tyres.

Trade shows should be measured only by how effectively they facilitate the connection between problems and solutions; suppliers and audiences; improvement and the tools required to achieve it. Ok, load cells and below-the-hook equipment are niche markets within a vertical industry where this is particularly true but every conversation is only as effective as it is advantageous for both parties.

Congratulations, LEEA. I look forward to unpacking the flight case at your first event of the New Year, wherever in the world that might be.

Lines of latitude

Before travelling to the Middle East and then the Far East, the topic of conversation at headquarters was North America as Straightpoint Inc. general manager John Molidor was in town for a week. It was important to review the year in person and go through our plans for Q1 2016 and beyond, while John also enjoyed a session with Gary Mullins, of Action Coach, a leading business coaching company that we have been using for a while. Of course, there was also time for a team dinner.

Straightpoint Inc. general manager John Molidor (centre of right row) enjoys a meal with the UK team during his recent visit.

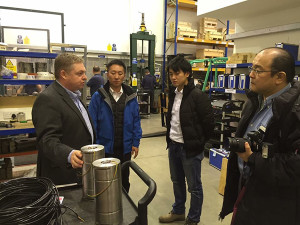

It was a busy start to the month that epitomised our global status with the visit of existing distributor, RUD Lifting Japan Co. Ltd., before we added a new partner to the family, Lenger d.o.o.

I last spent quality time with Osamu Hiramatsu, president of RUD Lifting Japan, and his team when we launched our new wireless load shackle at the Live Entertainment & Event Expo, which took place at the Makuhari Messe in Japan. They actually displayed our equipment at a number of trade events this year.

I led a tour of our building before we enjoyed an evening meal together. As is often the case with visitors, their highlight was our 350t vertical test machine, which is one of the most imposing pieces of equipment at our Havant, Hampshire facility.

Zagreb-based Lenger d.o.o., meanwhile, joined us as a distributor for Croatia. Boris Sadiku, its managing director, is cut from the cloth that suits the business to the Straightpoint family and I am very excited about working with him and the Lenger team. As always with all new and long-standing distributors, we will give Mr. Sadiku the product guidance and literature he needs to promote product to his marketplace.

I’ve shared advice before about growing through a distributor network. It is an effective way to provide a local service globally but one has to select their partners carefully. Lenger is established in the region—it was founded in 1992—and already distributes lifting equipment from leading manufacturers such as Germany’s Carl Stahl and Crosby, a North America-headquartered supplier of components. Lenger clearly ticks the history, pedigree, traceability and other boxes that we look for in a prospective new partner. Be clear about your own criteria.

Older and wiser

It’s been an interesting and challenging year in equal measure. When we approached the corner 12 months ago the lifting equipment industry was probably naively optimistic. Few foresaw the real consequences of the low oil price, euro rate against the pound or the knock-on effect of the waning Chinese economy, among other influences on the global economy.

We have been speaking about diversification at Straightpoint for a long time and 2015 has reiterated the importance of applying a product to a variety of industries, especially when the potential is as great as it is for load cells and force measurement technology. Constant improvement is important too, which is another fundamental part of our annual plan.

For example, we’ve improved safety and productivity when monitoring loads during heavy, critical and multi-point lifting applications by extending our range of wireless products to 700m (nearly 2,300ft) as standard from the New Year. The new range covers wireless products including the Radiolink Plus, Wireless Shackle Load Cell, Wireless Compression Load Cell and the wireless version of the new Running Line Dynamometer (or TIMH).

Thank you for reading my blog this year, which has approached nearly 15,000 words from January to December. I wish you every success in the early exchanges of another calendar year and remember to look out for a very significant personnel announcement next month.

Unfortunately, I missed Christmas jumper day at the office this year. Otherwise, I would have outdressed this lot and donned my red trousers.

Follow us on Twitter—@LoadCell—and use the hashtags #loadcell and #belowthehook.

Mr Loadlink